Basic goal underscores quality control techniques

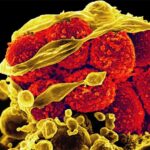

“Clean is better than dirty,” according to certified indoor environmentalist and licensed mold assessor, Mike Tebor, ASCS, CIE. Now on the surface that may sound like a descriptive oversimplification of indoor air quality control, particularly during a once in a century pandemic; but straight-talking Mike Tebor, founder and co-owner of Air Duct Aseptics (ADA) a company with a 30+ year history of specializing in indoor air quality control, claims that the simple mantra is the basis for his company mission. “We clean and contain mold (which generates musty odors), bacteria, dead skin flakes and other dangerous contaminants found in air conditioning systems as a vital measure to protect families and patients from the dangers of unclean indoor air,” he said. It is also where “simple” ends in his industry.

“Clean is better than dirty,” according to certified indoor environmentalist and licensed mold assessor, Mike Tebor, ASCS, CIE. Now on the surface that may sound like a descriptive oversimplification of indoor air quality control, particularly during a once in a century pandemic; but straight-talking Mike Tebor, founder and co-owner of Air Duct Aseptics (ADA) a company with a 30+ year history of specializing in indoor air quality control, claims that the simple mantra is the basis for his company mission. “We clean and contain mold (which generates musty odors), bacteria, dead skin flakes and other dangerous contaminants found in air conditioning systems as a vital measure to protect families and patients from the dangers of unclean indoor air,” he said. It is also where “simple” ends in his industry.The technology and techniques behind accomplishing that is where the rubber meets the road. ADA uses experienced, certified, and skilled professionals to identify problem sources, correct problems at the source and validate the results. Tebor conducted college level air conditioning and psychometric studies and had microbiological expertise from his previous career in quality control, sanitation and manufacturing roles at major beverage companies. He has maintained his recertification and licensing to qualify as an expert in HVAC systems and mold remediation, so he knows his way around achieving safe, cleanliness guidelines in both residential and health care facilities.

In addition to health benefits, clean air conditioning systems will save money. The U.S. Department of Energy reports that 25 to 40 percent of the energy used for heating or cooling a home is wasted. Contaminants, toxins and dirt from normal use require heating and cooling systems to work harder and shorten the life of your system.

When an HVAC system is clean, it doesn’t have to work as hard to maintain the desired temperature. As a result, less energy is used, leading to improved cost-effectiveness.

According to Tebor, finding and collecting contaminants found in miles of hospital and medical office AC duct systems is not confined to fiberglass, sheet metal and cooling coils which can block /restrict air flow increasing major electrical costs and consumer discomfort. Just as important, ADA removes and contains microbials (prevalent in Florida’s humid, hurricane-prone climate) which can trigger nasal congestion, respiratory problems, asthma attacks and skin irritation; not to mention the microscopic hazards of some mold speciates which can be potentially fatal in operating suites and Critical Care units. The company works with hospitals during construction, remodeling, high infection rate experiences and everyday operations to provide the safest methods to clear ductwork and contain residue.

Throughout his career, consumer awareness and government regulation of infection rates has heightened the importance of on-going maintenance of air filtration and data-driven results validation. Safety first is standard operating procedure along with strict adherence to National Air Duct Cleaners Association (NADCA) guidelines to ensure the highest safety and quality standards.

In contrast to the common adage, Tebor explains that indeed What you can’t see CAN hurt you. In fact, inspecting and cleaning HVAC duct work is just the beginning. In order to avoid spreading minute particles not visible to the naked eye which can contaminate the hospital indoor air quality, ADA uses HEPA filters to contain the micro-organisms that pollute the indoor environment. Also, in order to prevent and extend the sanitation process, ADA uses technology such as ultraviolet lights in strategic mold prone areas in conjunction with the sanitation process to kill biological viruses, bacteria, mold and musty odors and inhibit future growth, with a specific focus on specialty treatment units. The ultraviolet light produces an electromagnetic energy that can scramble the DNA of mold and bacterial follicles on surfaces and in the air to address contamination. In order to be effective, ultraviolet light must have direct contact within a specified distance and duration (similar to sunlight). Licensed mold assessors and certified Indoor environmental credentials, both held by Tebor, are essential in the safe handling of ultraviolet light techniques.

Since 1990, Tebor has led the company with his wife. Petrina, a co-owner whose HVAC hygiene field career was inspired because her asthmatic condition was adversely impacted by mold, is also a certified indoor environmentalist and licensed mold remediator and Class A air conditioning contractor. The company is headquartered in Pompano Beach and services the state of Florida with staffing and resources including a dozen mobile units.

Any initial inquiries can take advantage of a free consultation with ADA to discuss appropriate treatments.